Pneumatic Standard Pulp Valve

Bladed pulp valves’ features

A bladed pulp valve is one of the ideal solutions for fluid control in a restricted area. The reason why it is called as pulp valve is the fact that it is used commonly in paper and cellulose industries and that it runs with pulp in consistence. Operation problems occur continuously in other solutions (globe, conical, plain dampers) due to fiber deposits, entrapment and cleaning.

Usage areas

A single stainless steel plate that undertake opening & closing (in various forms) and availability of a direct flow area in the housing ensure a smooth operation conditions.

1- In cellulose and paper industryA- At inlets and outlets of all equipments2- In treatment and wastewater systems

B- On pipelines (pulp and fresh water)

C- As Tank Discharge Valve

D- As regulatory valve

3- In water and irrigation systems

4- In other suitable processes

Valve types

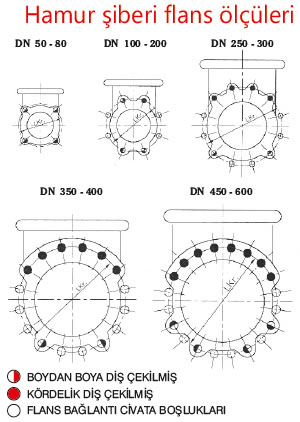

A- Depending on type of the housing

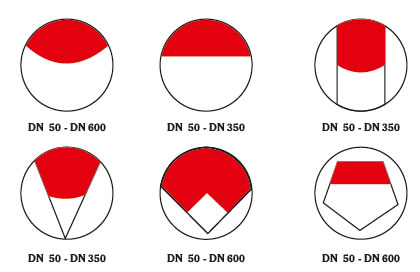

1- Standard Direct flow valve A- Altı Kapalı B- Altı GelenliB- Depending on type of the blade

2- V-flow adjusting valve A- Altı Kapalı B- Altı Gelenli

1- Standard Direct flow valve A- Blade end semi rounded B- Blade end plainC- Depending on the way through which it is driven

2- O-Bore Blade full flow

3- V-Blade adjusting valve

1- Hand wheel

2- Pneumatic control

3- Engine-driven

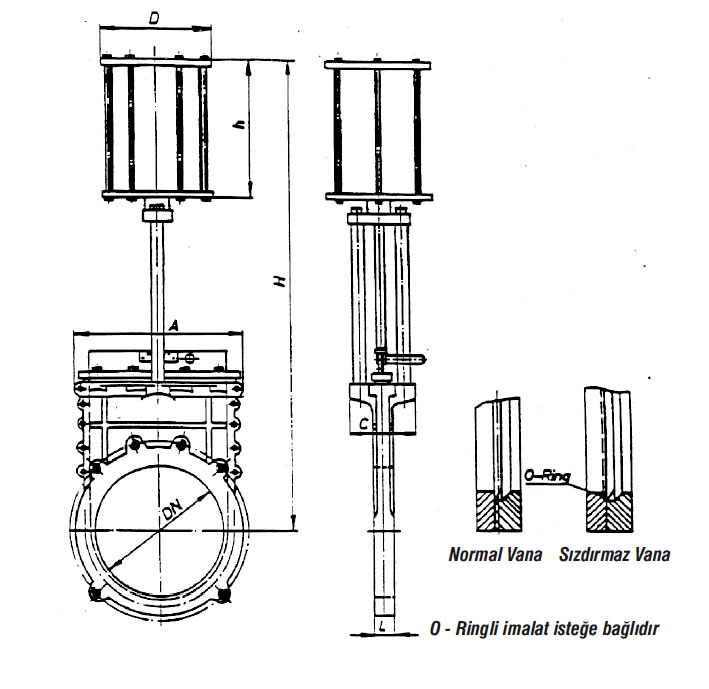

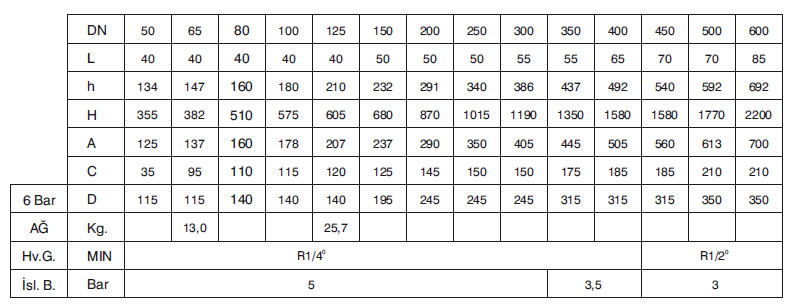

Technical issues

1- Operation pressure Max 4-6 Bar2- Operation temperature 80 0C (depending on type of the material)

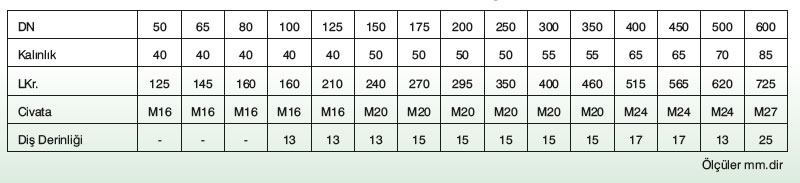

3- Flange connections satisfy Nd16 Standard.